Amherst, MA – The Life Science Laboratories building at UMass Amherst was designed to foster excellence in research while reducing energy consumption. To prevent thermal bridging where 40 steel cantilevers penetrate the building envelope, Wilson Architects and Lim Consultants specified structural thermal breaks, reducing energy loss by 50% where utilized and contributing to the project’s LEED Gold certification.

The five-story 310,000sf Life Science Laboratories building is designed to foster collaboration among faculty and student researchers in biology, environmental science, physics, chemistry, and other sciences. It also employs a range of advanced measures to slash energy usage, carbon emissions, and related costs.

Construction of the Life Science Laboratories building began in 2011 and was completed in 2013. Currently, the building houses 64 faculty, 512 student researchers, and 37 staff. However, it was designed for flexibility to reconfigure interior spaces to accommodate changes in direction of scientific research and in staffing.

Construction of the Life Science Laboratories building began in 2011 and was completed in 2013. Currently, the building houses 64 faculty, 512 student researchers, and 37 staff. However, it was designed for flexibility to reconfigure interior spaces to accommodate changes in direction of scientific research and in staffing.

With the energy-saving technologies in place, including structural thermal breaks for the canopy support structure, the lab saves approximately $300,000 in energy costs per year, which bears out the energy modeling that Wilson Architects conducted at the project’s outset. As the building systems are constantly monitored for energy usage, savings were documented to the extent that, in 2015, the building achieved LEED Gold certification.

Sustainability is especially challenging for a research facility, which typically consumes more energy than comparable buildings due in part to ventilation systems that draw large volumes of interior air through fume hoods and expel it into the atmosphere.

To meet safety and functional requirements of the building while minimizing energy use, Wilson Architects and Lim Consultants specified low-flow fume hoods and plumbing fixtures, energy-recovering air handling units and heat recovery chillers, water reclamation and recycling systems, sensor-controlled lighting, and water-cooled (versus less efficient air-cooled) systems, while maximizing the effect of sunlight.

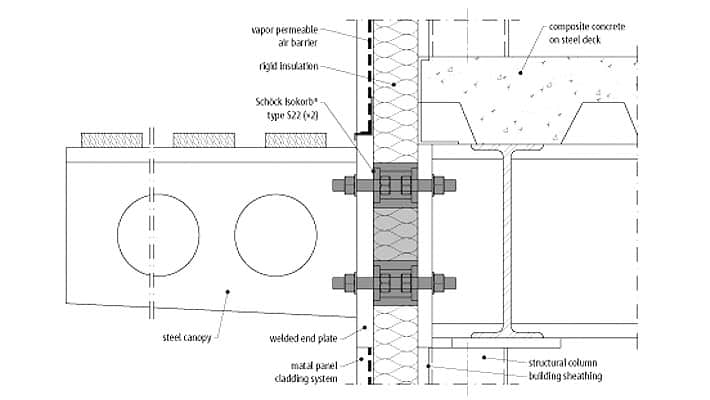

An additional energy-saving strategy was required to mitigate the potential of thermal bridging through steel beams that penetrated the insulated building envelope to support a 300-ft. glass canopy spanning the length of the building’s façade.

Architect Kevin Triplett of Wilson Architects Inc. explained, “We designed an elevated exterior walkway to make it easier for occupants to traverse the length of the building and, in particular, to provide handicapped individuals with easier access to entry points. To protect everyone using this external walkway from the elements, we built a glass canopy overhead, supported by multiple steel beams that cantilever from the building.”

However, exterior steel cantilevers supported by interior structural steel would cause interior heat to be conducted through the cantilevers and dissipated into the environment, requiring steel-to-steel insulation in the form of structural thermal breaks, or STBs.

The canopy support structure consists of 40 steel beams spaced approximately 10 feet apart. Wilson Architects specified an Isokorb Type S22 STB to be positioned where the cantilevers penetrate the insulated building envelope, reducing heat loss by approximately 50% at each penetration.

Supplied by Schöck North America, the STB is a load-bearing thermal insulation element consisting of a 3 in.-thick (76 mm) block of HCFC-free polystyrene foam held captive between steel plates with high-tensile threaded stainless steel bolts and nuts.

“Lim Consultants recommended that we install the S22 thermal breaks for steel construction to prevent thermal bridging,” Triplett said. “At the time, the product and technology were relatively new to us, but Schöck had fully tested its system and established a track record of success in Europe. Plus, they provided any technical support we needed.”

—

According to Triplett, it is difficult to calculate how much of the total savings accrued from the structural thermal breaks, because they were not separately metered and monitored. However, he says they contributed significantly to the savings.

He adds, “They also prevent the interior side of the penetration from becoming cold enough to form condensation, which can rust steel structures. Condensation can also support mold growth on adjacent surfaces, potentially affecting the health of occupants as well as the work done in the labs. That’s a problem which is difficult, if not impossible, to go back and try to fix. The STBs prevent condensation and contribute toward making the building sustainable for the long term. It’s a relatively small investment that yields big returns.”