Editor’s Note: This text is part one of a two-part series article.

Most designers know that masonry is inherently a green building material. Masonry has many attributes

that contribute to its sustainability including protection against rot, mold, and termites. Greater resilience

translates into lower maintenance costs and reduced use of virgin materials. Masonry’s strength and ability

to withstand severe weather and fire are helping to meet new demands for climate-resistant building

materials. Moreover, concrete masonry’s (CMU) thermal mass benefits can reduce energy bills and improve

thermal comfort in buildings.

CMU has come a long way, since the term “cinder block” was coined, and there are many aesthetic options

for both structural CMU and non-structural veneers. A polished CMU gives a contemporary, sleek look,

where matte ground finishes are subtler, and split units give a rugged “rock-like” feel. With a wide range of

materials, textures, and colors available, the design possibilities of CMU are endless.

What makes masonry sustainable?

Masonry is strong, resilient, durable, sound-reducing, and beautiful. One of the most important sustainable

attributes of CMU is thermal mass, or its ability to absorb and store heat. In the northeast, the best way to

utilize thermal mass is to help hold the temperature of conditioned spaces. The energy code recognizes

the benefits of thermal mass. In the 2012 IECC, for climate zone 5, the prescriptive requirement for a mass

wall is a U-factor of 0.078 (R-11.4). Comparing this to a wood framed assembly, which has a U-factor

requirement of 0.064 (R-20), or to a metal building with a U-factor requirement of 0.052 (R-26), utilizing

thermal mass reduces the amount of wall insulation required.

Methods to improve masonry’s sustainability

CMU has a lower cement content than other concrete, since it gains additional strength through vibration

and compaction. In addition, the environmental footprint can be reduced further using supplementary

cementitious materials, or SCMs. One commonly used SCM in the northeast is slag, a byproduct from steel

production.

Jandris embraces sustainability

Many CMU producers are looking for ways to go above and beyond designer’s expectations by introducing

new elements of sustainability into their manufacturing practices. Committed to taking a leadership role,

Jandris has made several changes to their manufacturing process over the last decade, which has

improved plant efficiency and lowered their environmental impact. They utilize use thermal mass to cool

the facility, have lowered their kiln oil consumption by half and introduced a closed loop system in their wet

finishing facility to conserve water. Since installing solar panels, they have offset CO2 emissions by 949

tons. Jandris has also upgraded their manufacturing process to consume less Portland cement while

maintaining required CMU strengths, further lowering CO2 emissions. Jandris has also invested in

developing 3rd party verified EPDs for each mix design, which has helped identify potential inefficiencies in

their operations.

The next frontier in sustainability: sequestered CO2

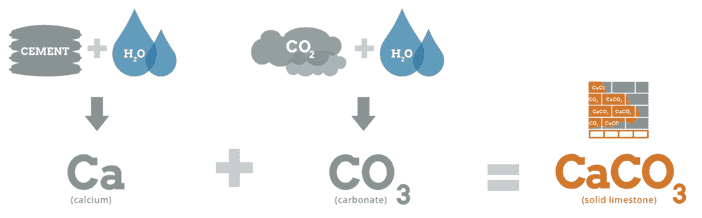

In March 2015, Jandris installed CarbonCure’s CO2 recycling technology into their Gardner, MA plant.

Jandris is among 36 concrete producers across Canada and the US that is using this innovative technology

to make better building products. CarbonCure’s technology recycles CO2 from smokestacks and injects it

into masonry during mixing, where it gets converted into solid calcium carbonate. This means the CO2 is

chemically converted into a stone within the masonry, and will never be released. The resulting masonry

products have a lower carbon footprint, and are now being specified by leading designers in Massachusetts.

What does this mean for my projects?

CMU is a sustainable building material that has endless design possibilities. Look for the second article in

this two-part series which will dive into how CMU can contribute to points in the new LEED v4 framework.

Heidi Jandris, LEED Green Associate, provides technical and design services forA. Jandris & Sons Inc. in Massachusetts.

Jennifer Wagner, LEED Green Associate and Vice President of Sustainability at CarbonCure Technologies in Halifax, Canada.